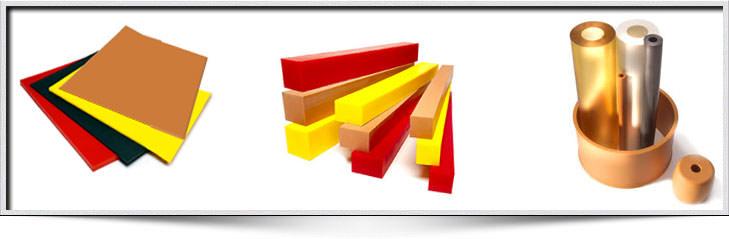

Polyurethane Bar Stock

Polyurethane Bar Stock

C.U.E. casts over 50 different sizes of precision molded urethane bar stock. Many common inch and metric sizes are currently available. This includes bars as small as 3/8” x 3/8” x 24”, up to 6” x 6” x 48” long. For special close-tolerance requirements, C.U.E. has the capability to custom mold urethane bar stock to your exact size specifications, with custom designed and built tooling.

In addition to precision molded bar stock, when dimensional tolerances are not critical, C.U.E. has the ability to mold non-standard bar sizes via an “Open-Cast” molding process without a tooling charge. Unlike precision molded bars, open-cast bars will typically exhibit surface imperfections, such as shrinkage marks, and size variations. However, they are ideal when appearance is not critical or when the intended application requires subsequent machining or fabrication of the bar. With our current capabilities, open-cast bars may be molded up to 144” in length.

Urethane bar stock from C.U.E. may be used unmodified in specific applications, such as a metal forming press brake die pad or paper industry cutting stick; or machined and fabricated into a prototype or final part configuration. Contact us to learn more or to check for your specific size requirements.

Availability:

While popular bar sizes are often available from stock, most bars are custom molded in the size, compound, and color that you request. Typically, an order will be produced and shipped in one to two weeks.

Hardness Range:

Our standard compound range from 45 Shore ‘A’ durometer to 60 Shore ‘D’.

<<Click for Details

Standard Colors:

While Tan is our primary standard color, Black, Red, White, Yellow, and Natural/Unpigmented are also available. The “Natural/Unpigmented” color typically varies depending on the compound selected, from a translucent honey color to hazy white as the material hardness increases.

FDA Food Handling

- Many C.U.E. urethane compounds in their Natural Unpigmented color comply with the requirements of Section #177.1680 of the FDA register for use as a dry food contact surface.

- Our WF-80 compound is available on a specialty basis for wet food contact applications.

Fabrication/Machining Guidelines

- Our urethanes can be efficiently machined using conventional machine tools and most woodworking tools. Heavy duty cutting tools must be used due to the friction developed while cutting.

- A conventional, high-speed, heavy duty drill is adequate for most drilling requirements. A sharp standard wood auger bit or a sharp twist drill bit will produce satisfactory results.

- A 20 – 80 grit wheel should be used when grinding with a surface speed of 6,000 – 8,000 feet per minute.

For more information about C.U.E.'s Urethane / Polyurethane Bar Stock call 800-283-4621 or click to contact us.